tests is in the“Accreditation Certificate and accredited tests list”

Since 2015 we are “ “DNV GL Examination Centre” for welding inspections, mechanical and metallographic tests and NDTs and we also are

“Bureau Veritas Italia Provider” for Analysis, Examinations and Testing Services according to EN, ASME and ASTM standards.

MECHANICAL TESTS

- Tensile Test

- Bend Test

- Fracture Test

- Impact Test

- Macro Examination

- Micrographic Examination

- Hardness Test (HV 0,1 ÷ 30)

- Heat Treatment

- Chemical Analysis

- Positive Material Identification (P.M.I.)

- Ferrite Measurement

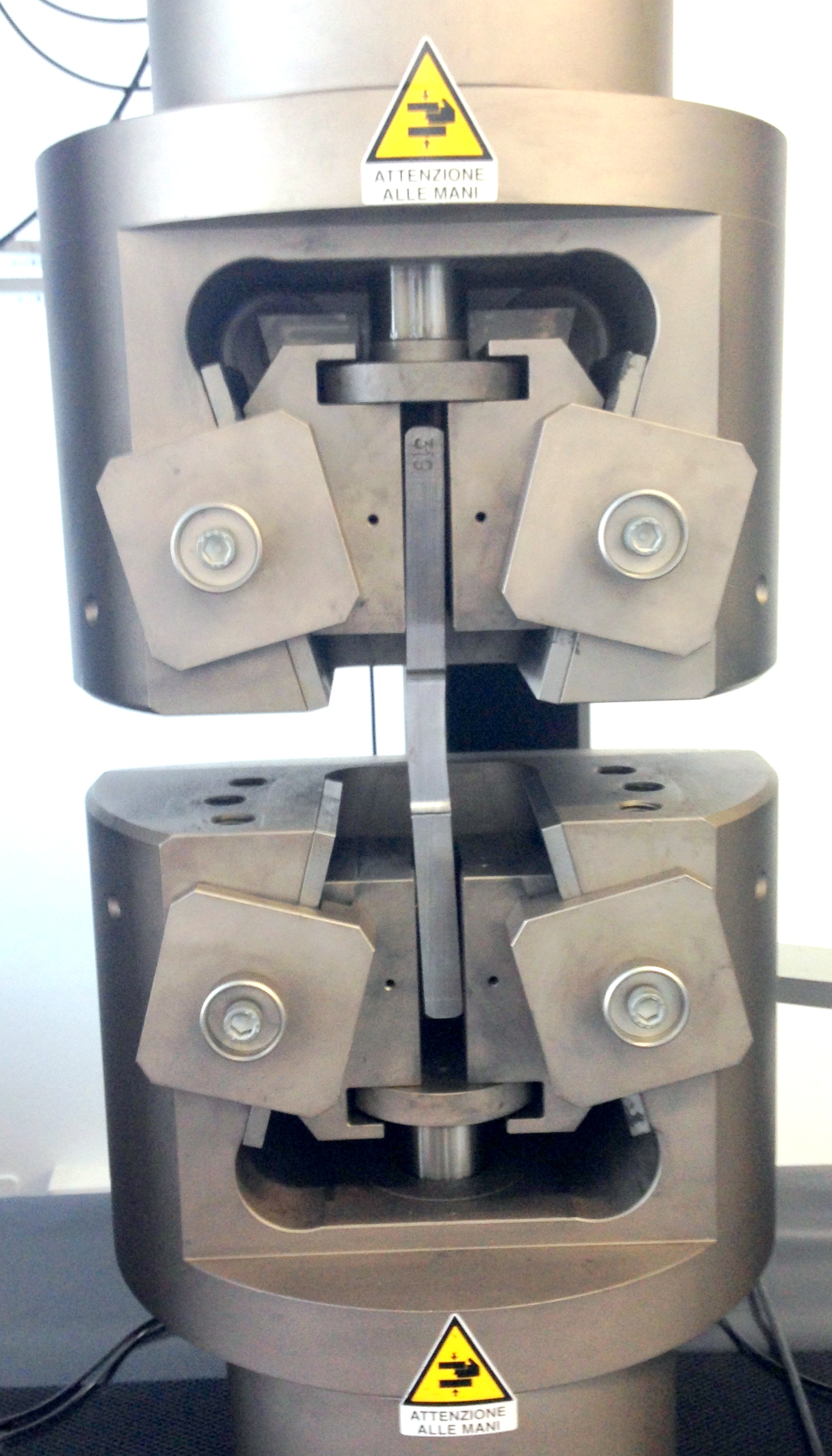

Tensile tests are performed at room temperature on prismatic and cylindrical samples, including those with threaded heads. |

| > |

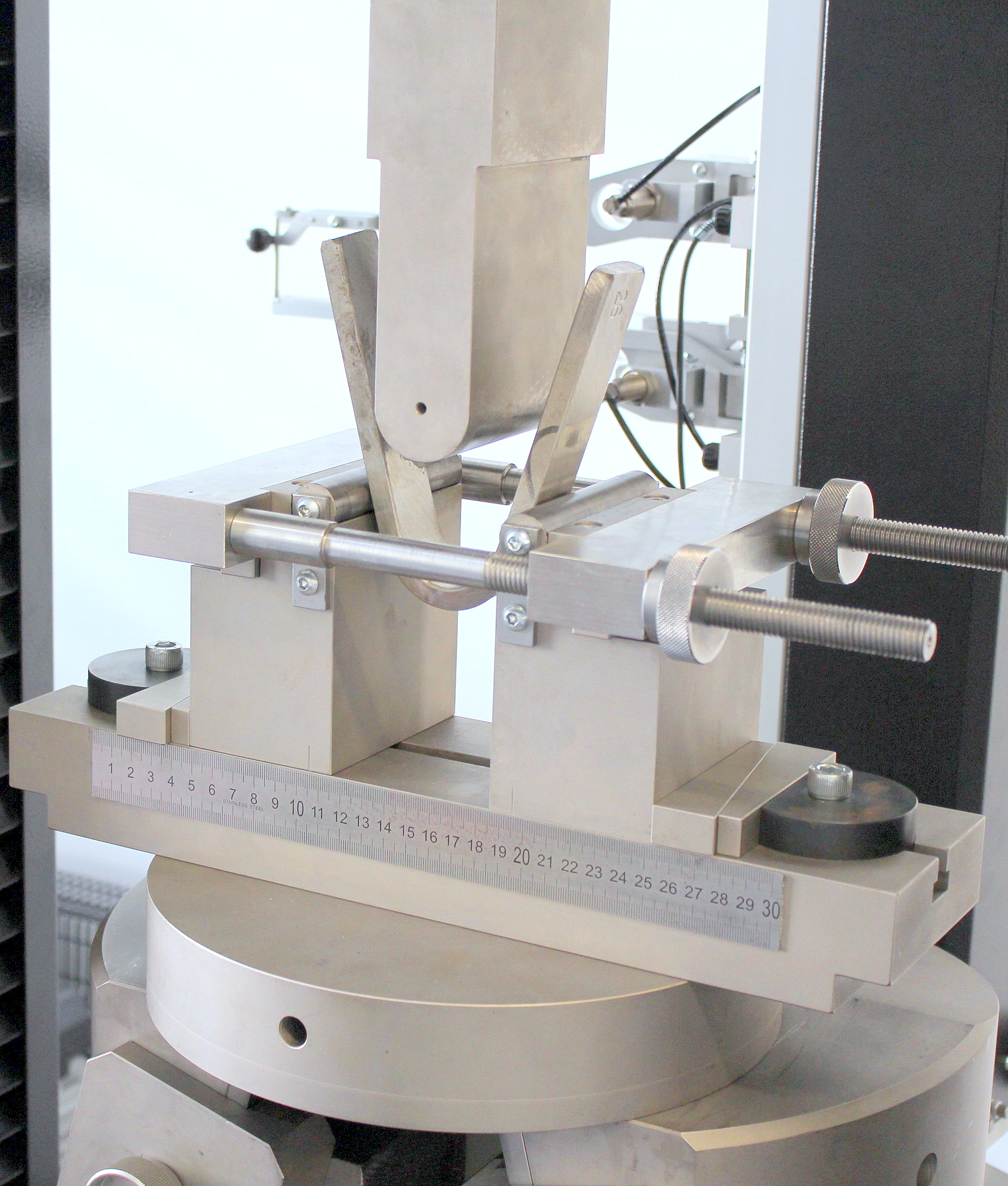

The bending test is a technological test that, by executing the bending of a sample with a standardized curvature radius, enables to identify the elasticity properties of materials in accordance to European and international standards. |

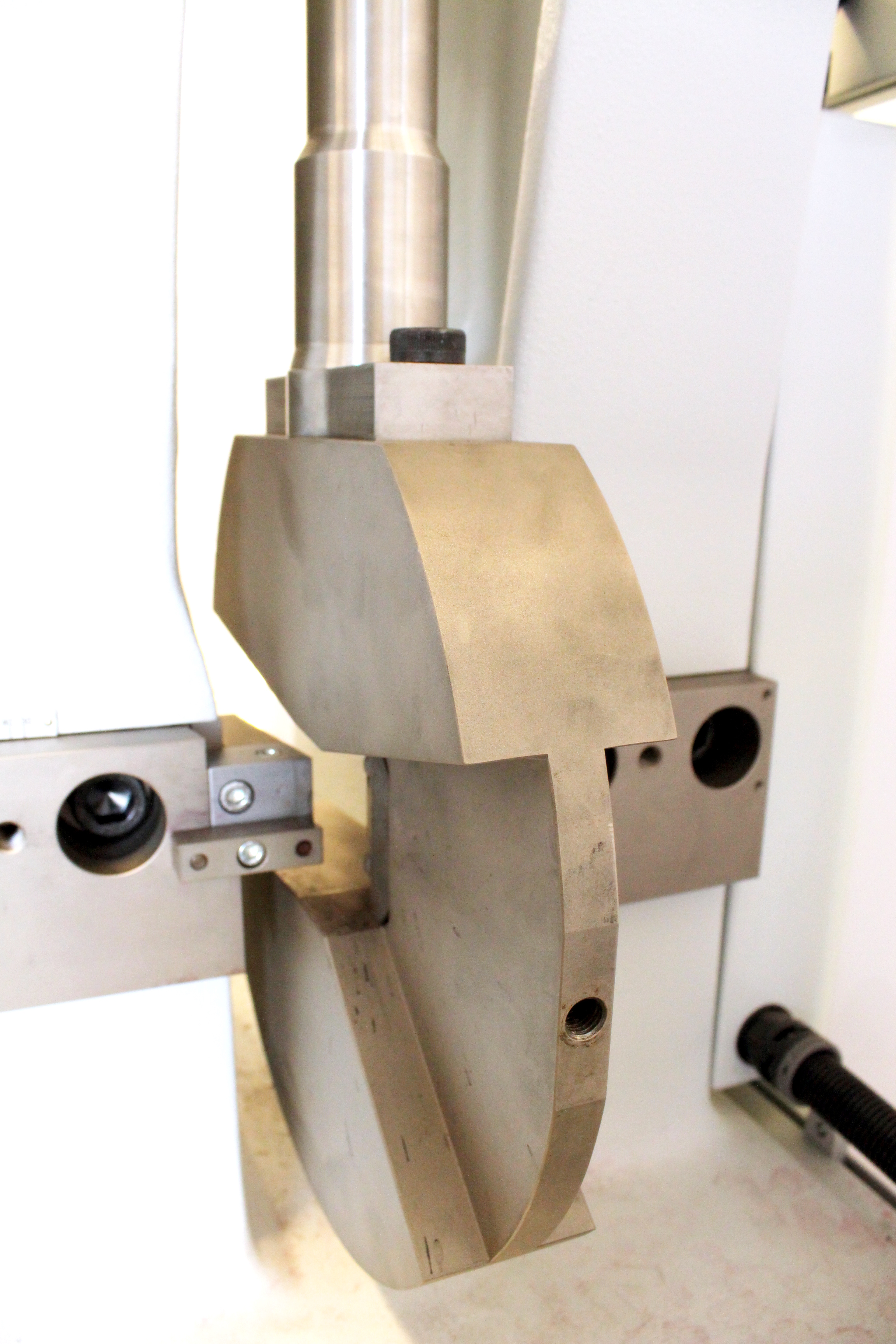

The fracture test is a technological test that, by creating a fracture on a welded sample, allows to detect any possible defective or incomplete fusion occurred during the welding process of the various materials, and to assess it in accordance to European and international standards. |

The impact test is performed according to the Charpy method at room temperature and at low temperatures, down to -196 ° C, for standard and reduced size samples.

This technological test allows to determine the materials' toughness resilience properties (impact resistance at various temperatures), according to European and international standards. |

The macrographic examination is performed on the joints made by full or partial penetration weld, as well as corner joint, butt-joints and T-joints; macrographic examinations are performed on multiple types of junctions, with common or special geometry (eg. tubesheet). |

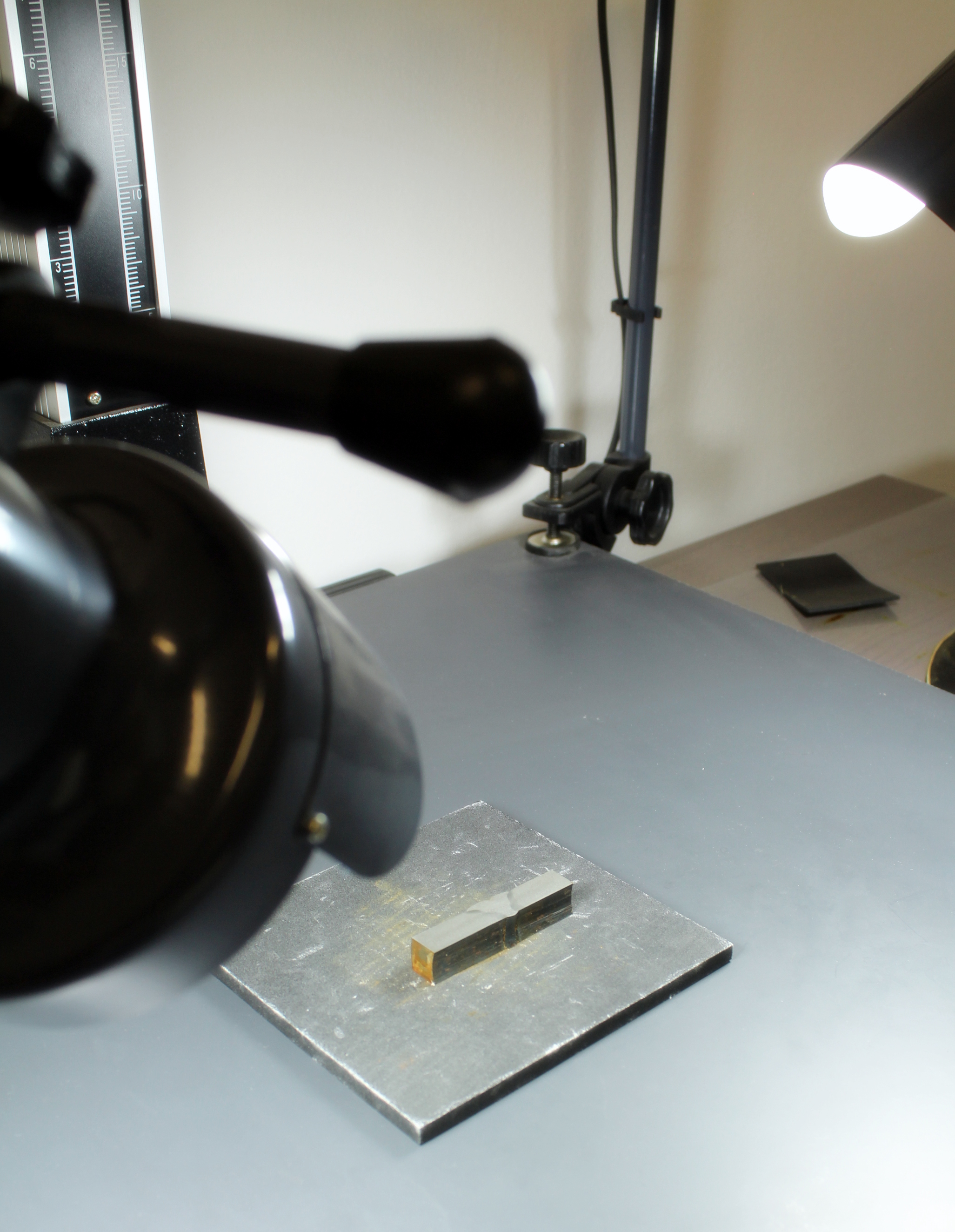

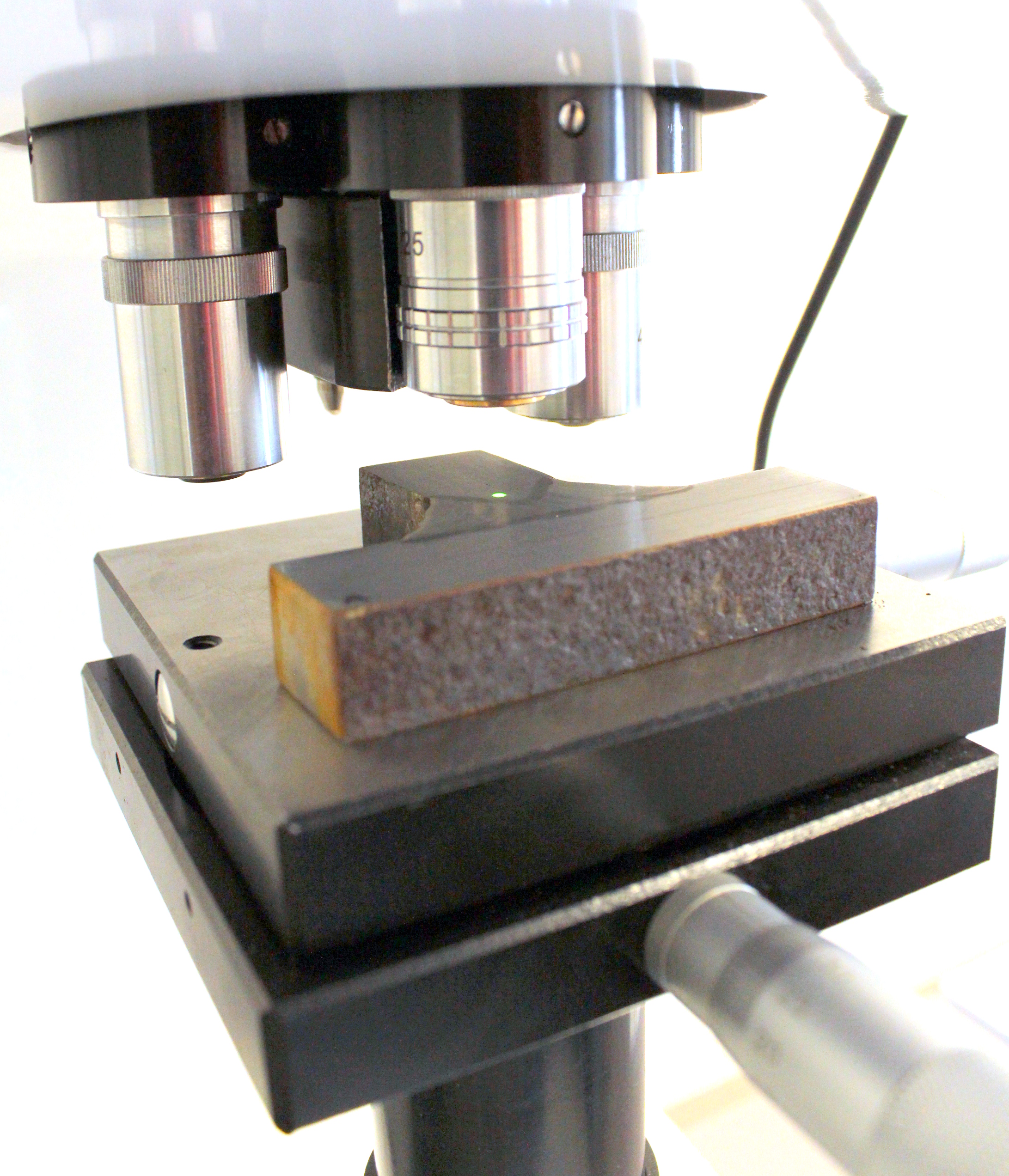

The micrographic examinations on metallic materials are a type of characterization of the materials performed with a microscopic examination that reproduces the structure of metals to identify the different intermetallic phases, their shape and distribution and to detect the size of the grain. |

The hardness test is performed using a durometer equipped to perform HV, HB, HRC and HRB hardness and microhardness tests. |

Our electric muffle furnace enables us to perform thermal treatments, by simulating the same characteristics and conditions as those that are to be performed during the production cycle. |

Chemical analyses are performed with quantometer SPECTRO MAXx LMM07 on all carbon steels and stainless steels, on nickel and its alloys, on copper and its alloys, on aluminium and its alloys etc. |

The P.M.I. (Positive Material Identification) is currently performed by an external laboratory working in partnership with our Company, and can be performed on all carbon steels and stainless steels, on nickel and its alloys, on copper and its alloys, on aluminium and its alloys etc. |

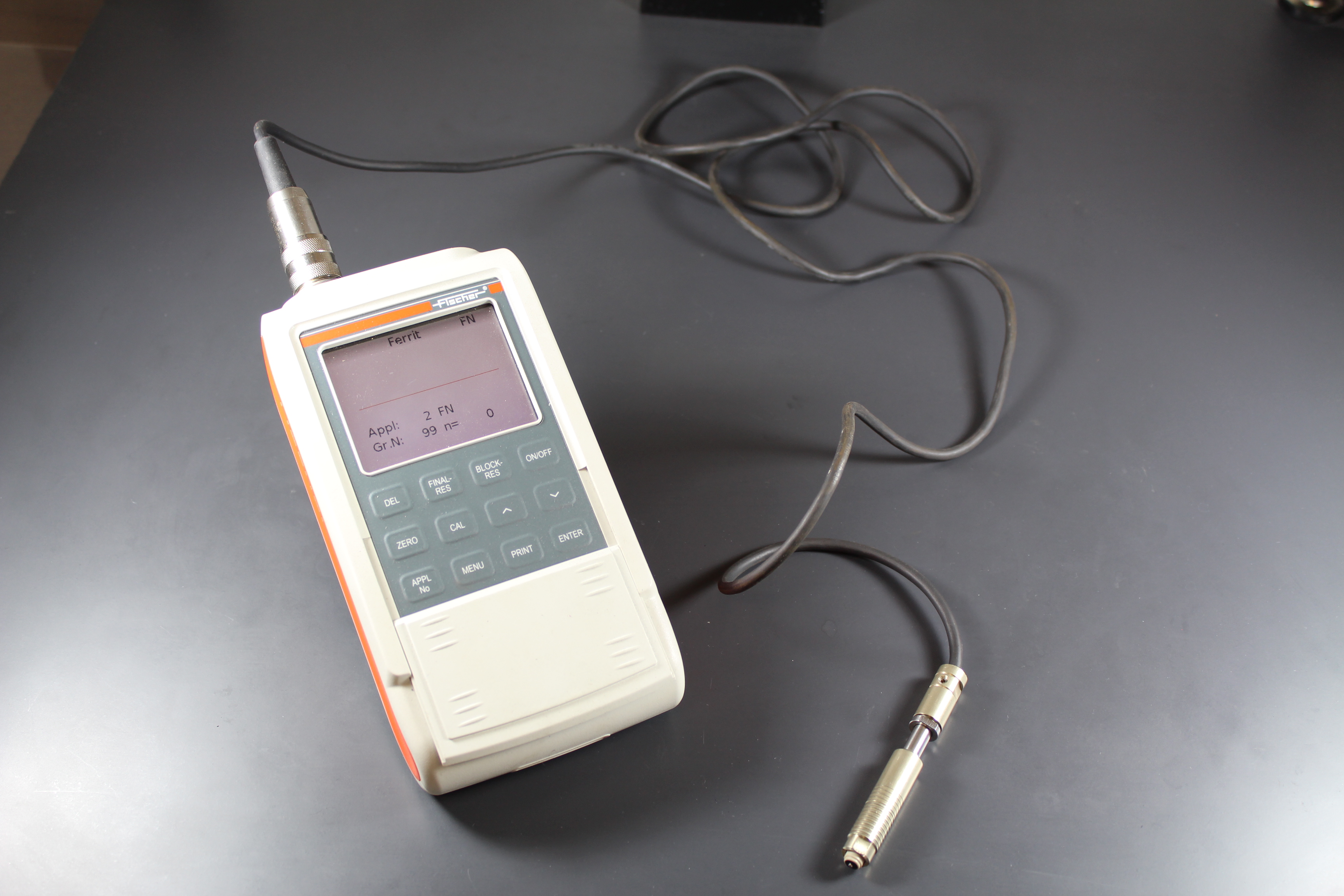

The measurement of ferrite content can be performed on all austenitic, duplex and super duplex in general, stainless steels materials. |